The Wimmenumer Mill

The Wimmenumer Mill is an indoor windmill built in 1774 with an octagonal shape. It was used to drain the 85-hectare Wimmenummer Polder, located between the lands surrounded by the Krommedijk and the formerly un diked Egmonder and Bergermeer.

Drainage of the polder was probably introduced around the middle of the 16th century, around the time these lakes were drained in 1565. A map from 1574, probably reworked in 1642, shows a seesaw mill at the location of the current mill, in contrast to neighboring mills indicated as upper millers. This is confirmed by maintenance bills from 1722 and 1732. This seesaw mill was destroyed by a summer storm in 1773 and replaced by the current octagonal mill.

The mill remained in operation until 1951, when it was replaced by a small electric auger pumping station. In 1953, the vacant mill was leased by P.Th. Zwijnenberg of Amsterdam and purchased two years later. After years of being used as a summer and weekend retreat, the mill was fully restored for milling in 1967.

Wimmenumer or Wimmenummer

Now the mill still serves as a vacation home, but since 1967 it has been in frequent use by its owner. There is uncertainty about the spelling of Wimmenumer or Wimmenummer (with 1 or 2 m’s at the end). According to existing spelling rules, the mill should be written as Wimmenumer mill (as well as Jelsumer, Dokkumer, etc.). But the officially established name of the polder is Wimmenummerpolder with 2 m’s.

About the mill

Equipment: Scoop wheel

Drive: Wind

Gear ratio: 1 : 0.72

Specifications: Scoop wheel: diam: 4.48 m, width: 30 cm; Head 0.4 – 1.2 m

Water shaft: Wood

Utilities – Electricity

- In 1950, an overhead power grid was built from a transformer station to the mill, requiring the polder to contribute to the Provincial Electricity Grid (PEN).

- In 1951, electric light burned for the first time in the mill, and in 1959 light was installed in the barn and toilet.

- In 1968 a 3-phase connection was made and electric baseboard heating was installed, and in 1970 the old-fashioned radiant heaters were replaced with panel radiators.

- In 1983, the distribution grid was made underground and the electricity poles were removed,

About the pumping station

The polder board had been improving drainage since 1930. Machinefabriek W. Hubert in Sneek received an order on Dec. 10, 1949, to build a diesel pumping station with a capacity of 12 m3/min. Electric pumping was considered, but was not yet technically possible.

In 1950, the position of the PEN changed and an electric auger pumping station could be built. On May 15, 1951, W. Moejes was requested to contact the president before beginning construction of the auger pumping station. Eventually, the Wimmenummer Polder received an electric screw pumping station.

The Mayor of Bergen opened the pumping station on Aug. 29, 1951, which is remarkable because at the time it was still part of the municipality of Egmond-Binnen. It ended up costing 9510.68 guilders and had to be operated manually. To turn the engine on, it was necessary to flip a main switch, press a button and then rev the engine with a star-delta switch. There was a float that could shut off the engine at the desired level, but it proved unreliable and was replaced after some time. As a result, the driver had to turn off the engine manually.

Jan Blom was the first machinist, followed by Klaas van de Oord and further by his brother Piet, Cor Bras and finally Cees van der Oord. From January 1, 1990, the work was taken over by the Long Round Rayon Management, first led by Cor Roelofsen and later by Jan Gootjes from January 1, 1996.

According to the accounts, the pumping station had a capacity of 12 m3/min, but measurements in 1984 showed that it was actually 14 m3/min. With higher water levels, however, the capacity decreased, unlike a scoop wheel in which the capacity increased with higher water levels. Several times it was observed that at higher water levels (-0.90 m NAP and above) the capacity of the mill exceeded that of the pumping station.

Construction drawing of The Wimmenumer

In 1974, technical draftsman Hein Rabe made a beautiful perspective drawing of The Wimmenumer. Rabe visited the mill himself, only twice, and otherwise drew everything from sketches and measurements I gave him.

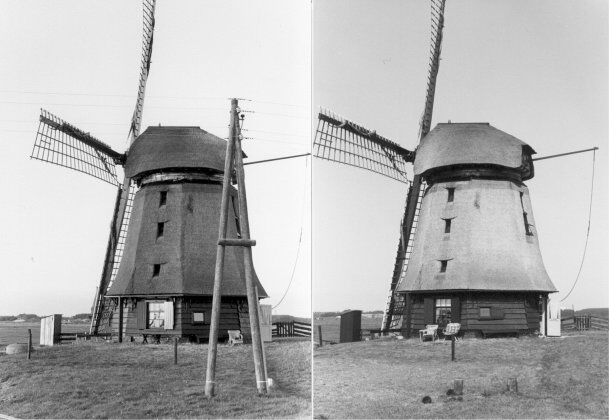

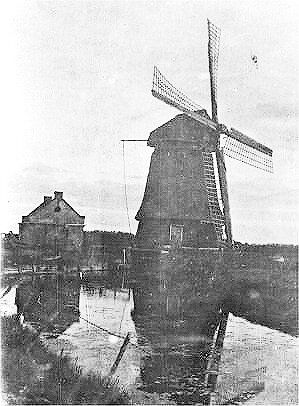

The oldest known photo of the Wimmenumer mill is from 1929

Photos from images collected on the internet

if you want a photo removed, please notify.

Rain Wells

The mill has wooden rain gutters on four fields. Rainwater from the mill used to run to the still-present stone well in the yard. It is a concrete ring with a convex concrete lid. Probably this well is from 1933. Indeed, in that year, millwright W.Moejes wrote to polder chairman N.Meijne that he “knew a best oak wine barrel of 700 liters for sale for f 16.50, on the wage at Alkmaar,” while a concrete ring with transport to the mill yard of 700 liters f 50.00 would cost and a 1000 gallon ring f 60,-. So it became a concrete ring.

My father once heard from a former mill resident that the water from this well looked all brown! No wonder when you know that when repairs are made, the thatcher pushes his bushels of reeds into a bucket of cow dung first! Delicious, that used to be drunk!

When we got water mains in 1962 this became a cesspool; the toilet in the mill drains into it. Rainwater from the mill is now drained directly into the ditch.

The square hole at the top was sealed with a stone tile with cement to prevent odor nuisance. The cesspool is in optimal biological balance; it has never needed to be emptied since 1962! One time, however, a hard plaque had formed on top, causing the toilet not to drain. That slice was then smashed with a stick and we put in (dried) bacteria. Since then, everything has been working perfectly again. And I now know: should the biological balance ever be upset again, flushing a dead bird down the toilet works wonders! And furthermore, don’t throw too many chemical cleaners down the toilet bowl!

When the well was almost empty in the summer, my father would crawl in, and clean it all the way inside. In the photo (March 1954), my brother Peter lowers it on a rope. Later, my father had a narrow ladder made especially for this purpose with which he could descend into the well. By August 1959 (a very nice dry summer), the well was empty. Ad and Jack Helder then drove a horse and cart with 16 milk cans full of tap water from the cheese factory on Hoeverweg via Cor Meijne’s land to the barn, and filled the well with it. The well is not used now, is empty (apart from some groundwater) and rainwater from the barn runs directly into the ditch.

Contact information

The Wimmenumer Mill was built in 1774 and can be visited by appointment.

Facebook: https://www.facebook.com/Wimmenumermolen-548228941921090

Website: http://www.wimmenumer.nl/

Owner: Eric Zwijnenberg

(Heiloo, May 1, 1946) is a Dutch physicist and volunteer millwright.

In 1997, Zwijnenberg was named a Knight of the Order of Orange Nassau. In 2016, he was awarded a Silver Carnation for his many years of efforts on behalf of mill conservation in the Netherlands in general and in North Holland in particular.

Email: [email protected]